Sunflower Oil Press

Definition of oil press

Screw oil press is a kind of edible oil processing equipment that operates on the principle of hydraulic full-automatic, and achieves continuous and efficient oil and grease pressing by rotating the screw shaft to propel the material billet. Its core advantage lies in compact structure, easy operation and high oil yield, which is widely used in the scenarios of individual households, small-scale oil mills and agricultural co-operatives, supporting the pressing of more than 30 kinds of oilseed crops, such as flower sunflower, peanut, soybean, rapeseed, castor seed and so on.

Table of Contents

- Definition of oil press

- Working video ofoil pressing machine for home use

- oil press machine industrial parameters

- Working principle of industrial oil press

- Edible oil press machine press oil introduction

- Sunflower oil production line configuration

- How to choose the right oil press equipment for you

Working video ofoil pressing machine for home use

The oil extraction principle of a screw press mainly uses the oil extraction screw to rotate in the pressing chamber and squeeze out the oil material. After adding the oil at the feeding port, the screw rotates to push the oil into the pressing chamber, causing the oil to gradually deform and separate from the oil through strong pressure. Meanwhile, the squeezed oil residue is discharged from the machine through the oil residue outlet and stored in the waste residue storage tank.

oil press machine industrial parameters

| Oil press model | 60 type | 70 type | 80 type | 100 type | 125 type | 150 type |

| Squeezing chamber diameter | 55mm | 65mm | 80mm | 101mm | 125mm | 150mm |

| Squeezing screw speed | 52r/min | 48r/min | 47r/min | 38r/min | 36r/min | 35r/min |

| Squeezing screw speed | 2.2kw | 3kw | 5.5kw | 7.5kw | 15kw | 18.5kw |

| Processing capacity | 30-60kg/h | 50-80kg/h | 65-130kg/h | 140-280kg/h | 300-400kg/h | 500-600kg/h |

| Overall weight | 220kg | 280kg | 780kg | 1100kg | 1280kg | 1420kg |

Working principle of industrial oil press

- The press screw is made of high carbon steel or chrome 40, quenched by high frequency, heat-resistant treatment, high hardness, wear-resistant, adaptable to high-temperature and high-pressure continuous operation, the service life of the traditional materials up to 8-10 times.

- The press chamber is designed as a progressive pressure structure, the diameter of the root garden of the screw gradually thickens and the pitch of the screw gradually decreases, which pushes the material embryo forward and produces turning and relative movement at the same time, destroys the colloidal structure of the oil material through friction and heat generation, and promotes the precipitation of oil and grease.

Multi-stage pressing and temperature control system for oil presses

- Adopting the principle of multi-stage propulsion and gradual pressurization, the pressure of the press chamber increases rapidly, realizing one-time fission and separation of oil.

- Equipped with infrared temperature control system, it automatically controls the pressing temperature (120-160℃) and moisture, softens and activates the oil molecules, improves the oil yield and guarantees the oil quality.

Spiral rod

Oil filter barrel

Filter element

Edible oil press machine press oil introduction

- Soybean: oil yield is about 12%-18%, and the crushed soybean cake can be used as feed or protein raw material.

- Canola (rapeseed): oil yield 30%-45%, is the main source of rapeseed oil.

- Peanut: oil yield 40%-50%, peanut oil has strong aroma and high market value.

- Cottonseed: oil yield 10%-20%, need to be pressed after detoxification treatment, cottonseed oil can be used for industry or food.

- Sunflower seed (sunflower): oil yield 25%-40%, sunflower oil is rich in unsaturated fatty acids.

- Sesame: oil yield 45%-55%, sesame oil (sesame oil) has a unique flavor and is suitable for cold pressing.

- Flaxseed: oil yield 30%-40%, flaxseed oil is rich in α-linolenic acid, suitable for healthy cooking oil.

- Perilla seed: oil yield 35%-45%, perilla seed oil has medicinal value.

Olive

Coconut

Flaxseed

Sesame

Palm fruit

Avocado

Peanut

Sunflower seeds

- Tea seeds: oil yield 20%-30%, tea oil is high-end cooking oil, storage resistance.

- Walnut kernel: oil yield 60%-70%, walnut oil is rich in nutrition, suitable for infants and children.

- Almond: oil yield 40%-50%, almond oil can be used in food or cosmetics.

- Coconut meat: oil yield 60%-70%, coconut oil is heat resistant, suitable for cooking or industrial use.

- Olives: 15-25% oil yield, olive oil is the core oil of the Mediterranean diet.

- Palm fruit: 20%-30% oil yield, palm oil is the most productive vegetable oil in the world.

Coconut oil

palm oil

peanut oil

Flaxseed oil

Sunflower oil production line configuration

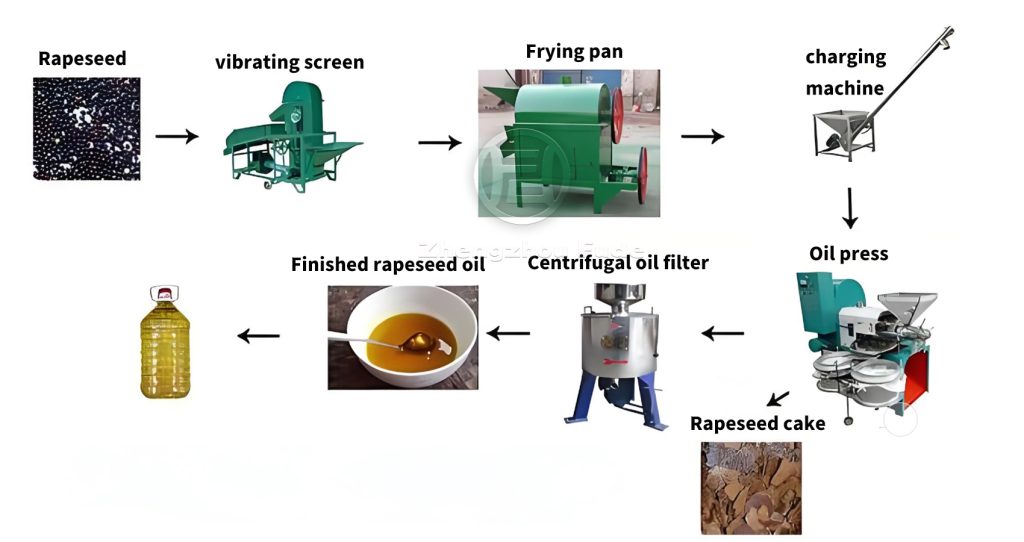

- Pre processing equipment (such as shelling machines, screening machines, and frying machines) requires cleaning, stone removal, shelling, and crushing of raw materials before pressing, so there are many types of pre processing equipment.

- oil press for home use equipment. The commonly used equipment currently includes oil presses and leaching equipment. Oil press equipment (hydraulic oil press, screw oil press).

- Refining equipment (filtration equipment). Refining equipment is the main equipment that determines the quality level of edible oil. The main processes of refining equipment include five processes: degumming, deacidification, dehydration, decolorization, and deodorization. Depending on the type of oil, such as tea seed oil, rice bran oil, and other oils with high wax content, a set of dewaxing equipment needs to be configured after deodorization.

How to choose the right oil press equipment for you

- Hot Pressing vs. Cold Pressing: What’s Best for Your Business?

- The choice between hot pressing and cold pressing is a business decision that affects your oil yield and product quality. Your screw oil press machine can handle both methods. The difference happens in the pre-treatment stage, before the seeds even enter the press. As a factory-direct manufacturer, we can configure a full production line that is perfectly suited for the type of oil you want to produce.

- Hot Pressing: For Maximum Yield

- Hot pressing is the most common commercial method. It means you heat the oilseeds in a roasting machine before you press them. Heating the seeds to around 120°C does two important things. It lowers the moisture content and it cooks the proteins inside the seed. This fully breaks down the cell walls, making it much easier for the oil to escape.

- For your business: This method gives you the highest possible oil yield. You get more oil from the same amount of seeds, which means more profit. The resulting oil also has a strong, roasted aroma that is very popular for general cooking oils.

- Cold Pressing: For Premium Quality

- Cold pressing means you press the raw seeds without any pre-heating. The temperature during extraction is kept low, usually below 60°C, generated only by the friction inside the press. This gentle process is designed to protect the natural qualities of the oil.

- For your business: This method produces a higher quality oil. It preserves the natural flavor, color, and valuable nutrients like vitamins and antioxidants. This “virgin” or “extra virgin” oil can be sold at a much higher price to health-conscious consumers or gourmet markets. You will get less oil per ton of seeds, but the value of each liter is much greater.

A screw oil press machine is a powerful and essential tool for any oil production business. It offers a reliable and efficient way to extract oil from a huge variety of seeds. Your choice between hot and cold pressing will define your product and your market. Most importantly, selecting a model with the right capacity for your business scale is key to your success. Partnering with a manufacturer who can provide a complete solution, from pre-treatment to filtration, will make your journey into oil production much smoother.

Contact us now for a professional yet free quote.

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business